Collaboration will help expand continuous flow technology into a growing market

Amagasaki, Hyogo Japan — Corning Incorporated, one of world leaders in materials science, and NARD Institute, Ltd., a contract synthesis and research company, have recently established an Advanced-Flow™ reactor (AFR) application-qualified lab (AQL) at NARD’s headquarters facility in Japan. Application qualified labs enable AFR customers to effectively access continuous-flow demonstrations, experimental trials, feasibility testing, and chemical reaction process development. The collaboration will allow Corning and NARD to expand continuous-flow process development capabilities in Japan’s pharmaceutical and specialty chemical markets and meet the growing needs of these industries.

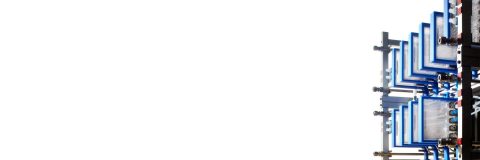

This lab facility, the first in Japan, will offer AFR testing, experimental trials, process development services, and continuous-flow demonstrations for customers. Additionally, the lab will feature Corning’s Lab Reactor and G1 reactor systems, allowing current and potential customers to evaluate Corning Advanced-Flow reactor systems and identify appropriate processes that can be transferred seamlessly to industrial production. Corning’s AFR business currently has 14 AQLs at customer locations around the world.